PU Ester-Based Polyurethane Tubing is a type of tubing made from polyurethane (PU) with an ester-based formulation. It is known for its excellent abrasion resistance, oil resistance, and chemical resistance.

This type of tubing is commonly used in pneumatic, hydraulic, and other applications that require high durability and flexibility. Compared to traditional materials, PU ester-based tubing offers enhanced elasticity, allowing it to withstand higher pressures and temperature fluctuations, making it ideal for complex routing systems.

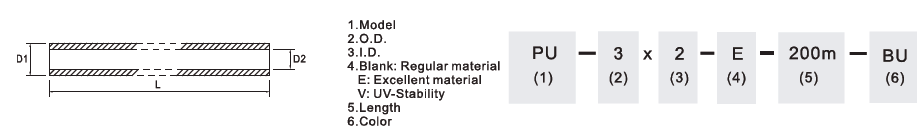

Ordering Code

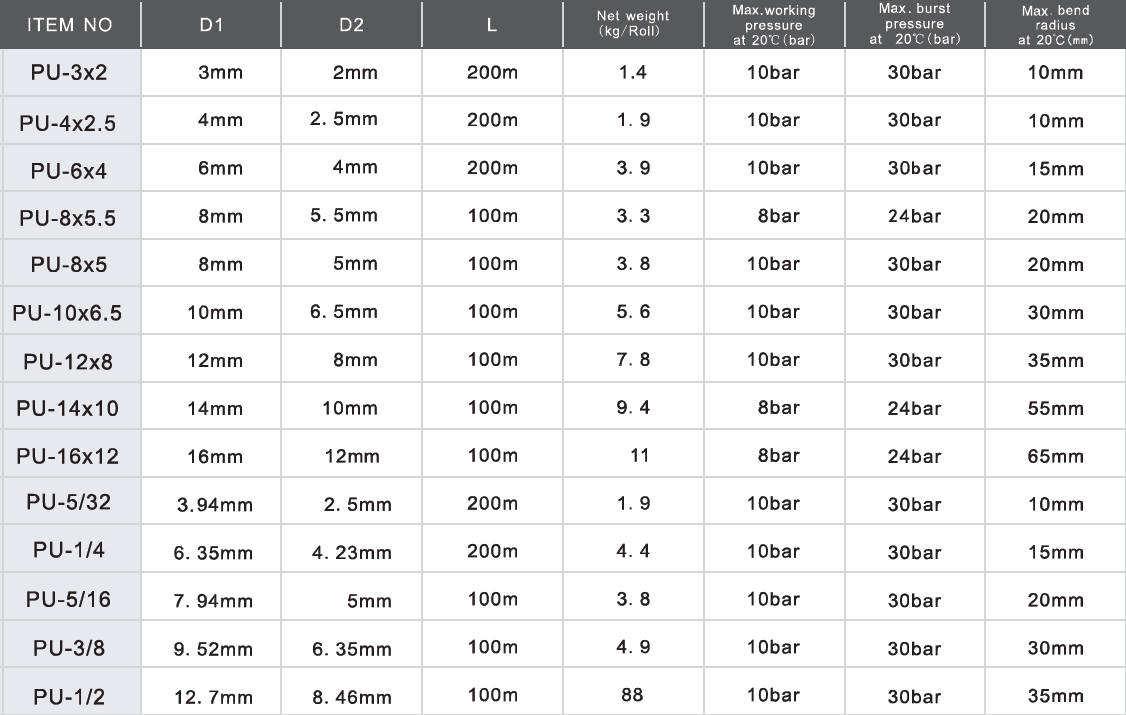

Specification

| Material | Thermoplastic Polyurethane |

| Applicable medium | Air, Water, Vacuum |

| Embient and fluid temperature | -20°C-+80°C |

| Hardness Shore A | 95A ASTM D-2240 |

| Tensile strength(kg/cm°) | 600 ASTM D-638 |

| Ultimate elongation(%) | 490~590 ASTMD-638 |

| Taber abrasion(mg) | 30-40 ASTM D-1044 |

| Tear strength(kg/cm²) | 155 ASTM D-732 |

Characteristic

◆ Resists abrasion and impact

◆ Resists oil and many chemicals with no erosive nature

◆ Long working life

◆ Precise size and wall uniform

Application

◆ Industrial automation

◆ pneumatic tools

◆ tube for water,air and vacuum

Benefits of PU Ester-Based Polyurethane Tubing

Due to its high resistance to abrasion, chemicals, and pressure, PU Ester-Based Polyurethane Tubing has a long service life. This durability reduces the need for frequent replacements, lowering maintenance costs over time. It is a cost-effective solution in industries where uptime and reliability are critical.

The combination of flexibility, chemical resistance, and high pressure tolerance makes PU Ester-Based Polyurethane Tubing highly versatile. It can be used in a wide range of industries, including automotive, manufacturing, food processing, and fluid handling. Its ability to adapt to various fluids and pressures ensures it meets the demands of multiple sectors.

The flexibility of PU Ester-Based Polyurethane Tubing simplifies installation. The tubing can be easily routed through tight spaces without the risk of kinking, making it ideal for complex systems. Additionally, it is compatible with a variety of fittings and connectors, further enhancing its ease of use.

PU Ester-Based Polyurethane Tubing is typically more environmentally friendly than other types of tubing, as it is often recyclable. Its long service life reduces the frequency of disposal, contributing to a more sustainable operation.

Applications of PU Ester-Based Polyurethane Tubing

PU Ester-Based Polyurethane Tubing is used in a variety of industries and applications where flexibility, durability, and resistance to environmental factors are essential. Here are some common applications:

In pneumatic systems, PU Ester-Based Polyurethane Tubing is often used to transport compressed air due to its high pressure resistance and flexibility. It ensures smooth airflow, even in dynamic setups where the tubing may be subject to frequent movement.

The automotive industry uses this tubing for fluid transfer, fuel lines, brake lines, and other systems where flexibility and chemical resistance are required. The tubing can withstand exposure to oils, fuels, and hydraulic fluids, making it a reliable choice for automotive applications.

In hydraulic systems, PU Ester-Based Polyurethane Tubing is used to transport hydraulic fluids. Its high-pressure resistance and durability make it suitable for high-performance applications in industrial machinery, construction, and heavy equipment.

The tubing is also used in food processing and beverage industries where food-safe materials are necessary. It is resistant to oils, acids, and other substances that may be encountered during production, helping maintain product integrity.

PU Ester-Based Polyurethane Tubing is used in various industrial equipment, including robotics, packaging machinery, and medical devices. Its flexibility allows it to be used in precise applications where space constraints and durability are factors.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap