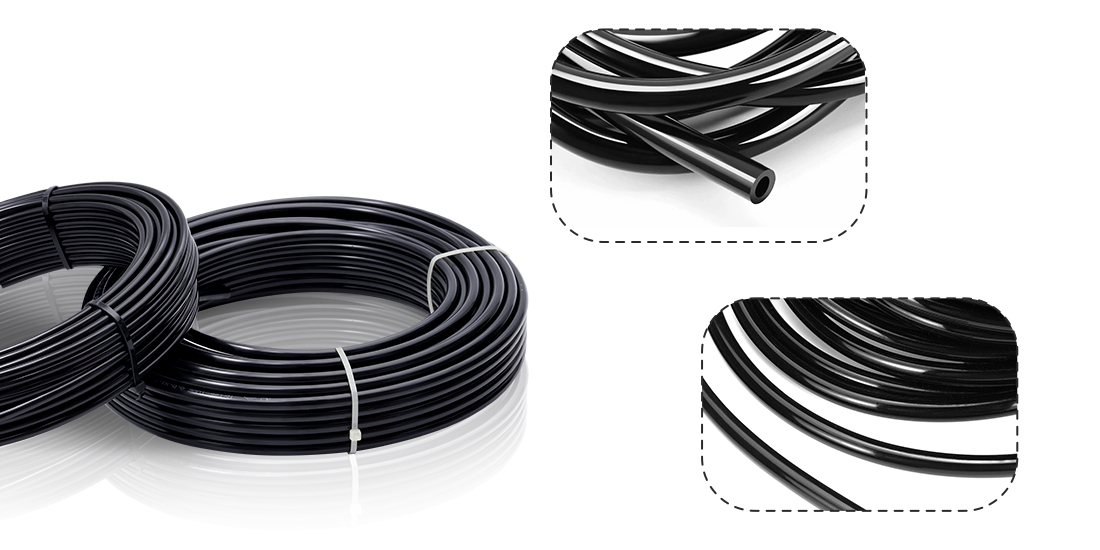

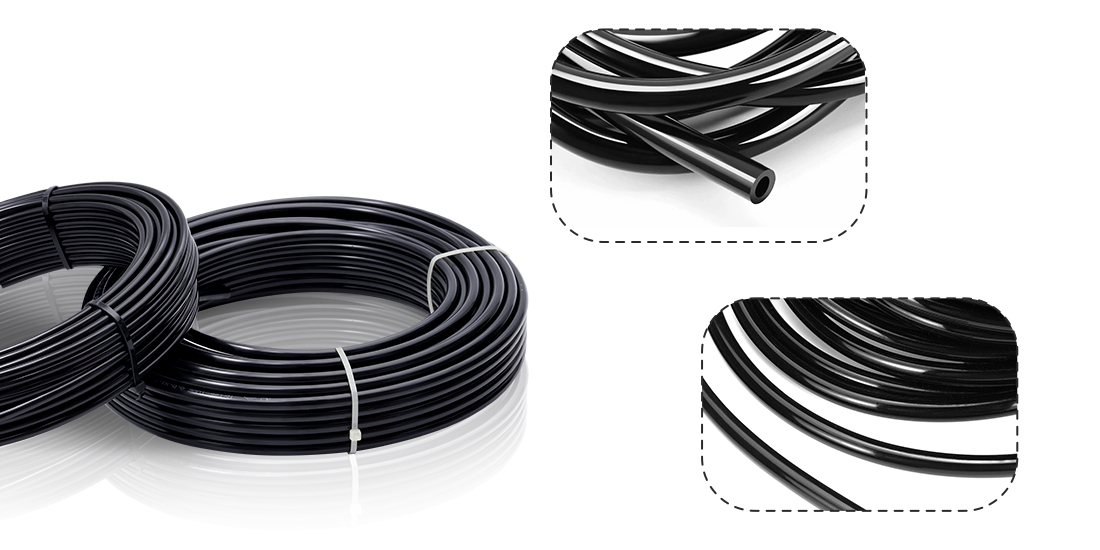

What is LLDPE Pipe?

LLDPE pipe stands for Linear Low-Density Polyethylene tubing,which is a type of Polyolefin Tubing made from LLDPE resin through an extrusion molding process, featuring excellent chemical resistance, crack resistance, flexibility, and UV resistance.

LLDPE pipe is widely used in industries such as low-pressure liquid transfer, fertilizer irrigation, water treatment, potable water systems, pneumatic lines, and food-contact applications, and provides function characteristics such as safe transport, impact resistance, weatherability, and low-cost processing.This kind of tubing is especially suitable for engineering scenarios that require a balanced combination of flexibility, corrosion resistance, and cost-effectiveness.

Characteristics of LLDPE Pipe

LLDPE pipe has the following characteristics that you need to understand.

◆ LLDPE has a more linear molecular structure with fewer branches compared to LDPE.

◆ LLDPE has a lower density, typically ranging from 0.915 to 0.935 g/cm^3, whereas LDPE has a density ranging from0.916 to 0.930 g/cm^3.

◆ LLDPE exhibits higher tensile strength and toughness, whereas LDPE is known for its flexibility.

◆ LLDPE generally has higher transparency and gloss compared to LDPE.

◆ LLDPE is produced using polymerization chemistry methods and is relatively newer in terms of manufacturing processes, while LDPE is traditionally manufactured using high-pressure polymerization methods.

In summary, LLDPE pipe combines flexibility with strength, making them an ideal choice for various industrial and agricultural fluid transportation applications.

LLDPE Pipe Application

LLDPE pipe has excellent flexibility and impact resistance, along with good chemical resistance and strong environmental stress crack resistance.

◆ Agricultural irrigation system

◆ Resistant to UV radiation and pesticide corrosion

◆ Horticulture and Greening

◆ Garden watering pipe, greening irrigation pipe

◆ Easy to manually set up, safe and environmentally friendly

LLDPE vs LDPE Pipe

In terms of molecular structure,LLDPE offers higher strength and better tear resistance with a more linear molecular structure, while LDPE is softer and more flexible with more branching.

LDPE is produced through high-pressure free radical polymerization, a process that is intense and random. LLDPE, on the other hand, is produced through a controlled and more precise low-pressure catalytic copolymerization process.

LDPE has a highly complex chain structure, with both long-chain and short-chain branches, making it highly branched and irregular. In contrast, LLDPE incorporates α-olefins, which introduce short-chain branches attached to the main chain, resulting in a more regular, continuous, and linear structure.

Due to the extensive branching in LDPE, the molecular chains are irregular and loosely packed, leading to large intermolecular spaces.

In LLDPE, the molecular chains, with their linear main chains and regular short branches, are more orderly and closely packed.

The differences in molecular chain structure result in variations in crystallinity between the two types of polyethylene, which in turn leads to differences in density and mechanical properties between LLDPE and LDPE.If you want to know the performance difference between the LLDPE and LDPE, you can browse this article.

LLDPE Pipe Specification

LLDPE pipes come in a wide variety of sizes. Common sizes are listed below.

1/2 lldpe tubing:Small-diameter LLDPE pipe has an outer diameter of 1/2 inch (approximately 12.7 mm) and a wall thickness of 1-2 mm. Available in black, yellow, blue, and transparent, it is suitable for landscaping, agricultural irrigation, gas, and drinking water transportation.

1/4 lldpe tubing:A kind of Micro LLDPE tube type and has an outer diameter of 1/4 inch (approximately 6.3 mm) and a wall thickness between 0.8 mm and 1.5 mm. Available in black and transparent, they are suitable for use in laboratories, medical equipment, and as consumables for 3D printers.

3/8 lldpe tubing:Commonly used for branch lines with smaller flows, this pipe has an outer diameter of 3/8 inch (approximately 9.5 mm) and a wall thickness ranging from 0.8 mm to 1.8 mm. Available in black, blue, transparent, and white, it is suitable for cooling water lines, low-pressure gas lines, and the food and beverage industry.

Conclusion

Fokca offers a variety of pipe types, including PP tubing, LDPE pipe, PE tubing, as well as PU tubing, nylon hose, PVC pipe, and more. Contact us directly for the latest product prices and complete product catalogs.