Jun 26, 2023

LDPE(low density polyethylene) and LLDPE(linear low density polyethylene), as two pillars in the PE family, show the diversity and excellence of plastic materials respectively. LDPE is light, soft and easy to process, playing an outstanding role in packaging, agriculture and other fields; LLDPE has a place in more demanding industrial and consumer product manufacturing due to its high strength, toughness and environmental stress resistance. What are the specific advantages and disadvantages of those?

LDPE is polymerized with oxygen or organic peroxide as catalyst under high pressure of 100-300MPa, so it is also called high pressure polyethylene.

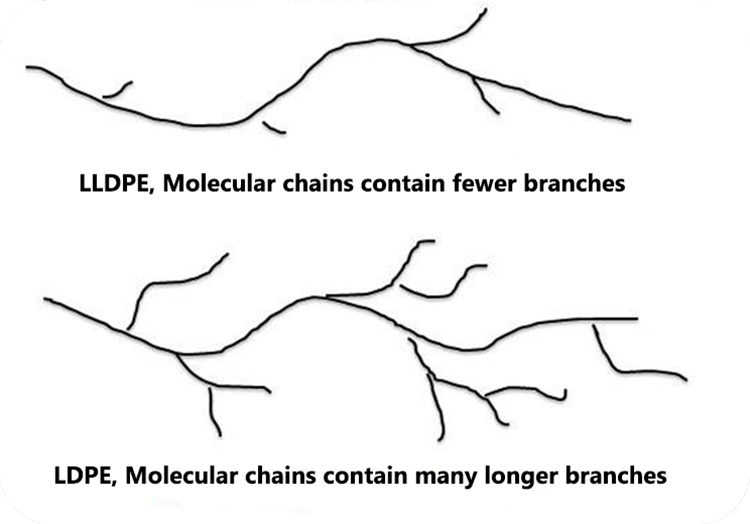

It has fewer polymer chains and requires less energy to break. There are many long branches on the molecular chain, and the crystallinity is low (55% - 65%), so the melting point is relatively low, about 105-115 ℃.

LLDPE is a copolymer formed by high pressure or low pressure polymerization of ethylene and a small amount of higher α - olefins (such as butene-1, hexene-1, octene-1, etc.) under the action of catalyst.

The molecular structure is characterized by its linear backbone, with little or no long branches but some short branches. This structure enables LLDPE to have high crystallinity and melting point, which is generally between 120 ℃ and 130 ℃.

Tensile strength: LDPE has a relatively low tensile strength due to a large number of branched chains in its molecular chain structure. In contrast, the linear backbone structure of LLDPE reduces the presence of long branched chains, thereby improving the strength of the polymer and its tensile strength is higher than LDPE.

Toughness: LDPE can absorb more energy without fracture when impacted or stretched due to the flexibility and deformation of its molecular chain, so it has high toughness, softness and ductility. The linear main chain structure of LLDPE and the coordination of short branch chains also make it show good tenacity.

Rigidity: LDPE has a relatively low rigidity due to its loose molecular chain structure and a large number of branched chains. In contrast, LLDPE is more rigid. Thanks to its high crystallinity, LLDPE maintains better shape stability under external forces.

Environmental stress cracking resistance: LLDPE has excellent environmental stress cracking resistance due to its linear structure and high crystallinity, making it better than LDPE in this respect.

Tear strength: LLDPE also has higher tear strength than LDPE. This gives LLDPE an advantage in applications requiring tear resistance.

LDPE has good chemical stability and is resistant to most acid, alkali and salt chemicals. However, it is less resistant to strong oxidants. LDPE may degrade or degrade under strong oxidizing environment. Also, it is poorly resistant to some organic solvents, such as aromatic hydrocarbons and chlorinated solvents, and may swell or dissolve in these solvents.

LLDPE also has good chemical stability and is resistant to various acids, bases and organic solvents. LLDPE may have slightly better solvent resistance than LDPE, but this also depends on the specific solvent type and concentration.

LDPE and LLDPE have good melt flowability, which makes them easy to form during processing.

LDPE has a wide melting temperature range, allowing operation within a wide processing temperature range, thereby improving the flexibility and stability of the processing process. It may produce certain shrinkage during the machining process, which needs to be considered and adjusted during the mould design and machining process.

LLDPE can bear more tensile force during processing, which is beneficial to manufacturing thinner and lighter products. In addition, the extrusion load of LLDPE increases and the calorific value also increases during extrusion molding, so corresponding equipment adjustment and optimization are required.

Air permeability: LDPE has certain air permeability due to its molecular chain flexibility and easy deformation. Although LLDPE has certain air permeability, it may be slightly inferior to LDPE, which mainly depends on its molecular structure and crystallinity.

Weatherability: LLDPE is generally superior to LDPE in weatherability and can maintain its performance unaffected over a wider temperature range.

Electrical insulation: both have good electrical insulation, which makes them widely used in electrical and electronic fields.

Transparency: LDPE and LLDPE both have certain transparency, but LDPE usually has higher transparency.

LDPE is widely used for manufacturing various packaging bags and preservative films due to its good flexibility, transparency and moisture resistance.

Meanwhile, LDPE is also used for manufacturing medical devices and packaging, such as infusion bags, disposable syringes, etc. due to its non-toxicity and good biocompatibility.

LDPE material is widely used as the insulation layer of wire and cable due to its excellent electrical insulation property and chemical stability.

LLDPE material is widely used in packaging industry, pipe and container manufacturing due to its excellent physical properties and processing properties, such as LLDPE pipe, LLDPE tube and LLDPE bags. In addition, LLDPE materials are used to make various daily necessities, such as plastic basins, bins, trash bags, etc.

Characteristics | LDPE | LLDPE |

Density | 0.910~0.940g/cm³ | 0.915~0.935g/cm³ |

Appearance | Milky white, odorless, odorless, non-toxic, waxy particles with a matt surface | Non-toxic, odorless, odorless milky white particles |

Polymerization method | Polymerized with oxygen or organic peroxides as catalyst under high pressure | Ethylene is polymerized with a small amount of higher α - olefin through high pressure or low pressure |

Molecular structure | Many long branched chains on the molecular chain | Linear main chains with little or no long branches, but with some short branches |

Crystallinity | Relatively low | Normal,but higher than LDPE |

Melting point | 105-115°C | 120-130°C |

Mechanical strength | Inferior | Superior |

Toughness | Good flexibility, extensibility and toughness | Good |

Chemical stability | Resistant to acid, alkali and salt solutions, but not to organic solvents | Resistant to acids, alkalis, organic solvents |

Processability | Good melt flow, but prone to strain hardening | Good melt mobility, less shear sensitivity, easier control |

Breathability | Relatively high | Normal |

Application | Agricultural, Medical, Packaging and Cable Materials | Agricultural film, packaging film, molding, pipe material |

FOKCA is a professional manufacturer of various flexible hoses. We provide a wide range of high-quality plastic pipes, include PA、PU、PC and PE. If you have any needs, please click here to visit our Product page.

You can also click here to access our Blog pages. We offer a range of more detailed and comprehensive articles, pictures and videos to help you better understand plastic pipes.

You May Interest In

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap