Jan 16, 2025

The history of threads can be traced back to the Industrial Revolution in Britain. Since its inception, threads have been widely used in various industries, including the machinery industry, automotive manufacturing, aerospace, electronics, and furniture, due to their advantages of easy assembly, good sealing, high strength, high transmission efficiency, and standardization.

In daily life, common items like refrigerators, televisions, tables, chairs, and even the internal components of mobile phones and computers contain threaded parts. It can be said that threads have become deeply integrated into our lives.

Connection fittings are generally used for fluid transmission, responsible for connecting pipes and components. These fittings typically use threads for connection, which are referred to as pipe threads.

If you want to know how pipe threads are measured, please refer to How to Measure Pipe Thread?.

Pipe threads are a type of thread that differs from common fastening threads. They are specifically designed for connecting pipes. These threads are finer and shallower to prevent excessive weakening of the pipe wall. Pipe threads are widely used in fluid transmission systems for liquids, gases, and other media.

The main function of pipe threads is to create a sealed connection between pipes or fittings through threading, thereby preventing leakage.

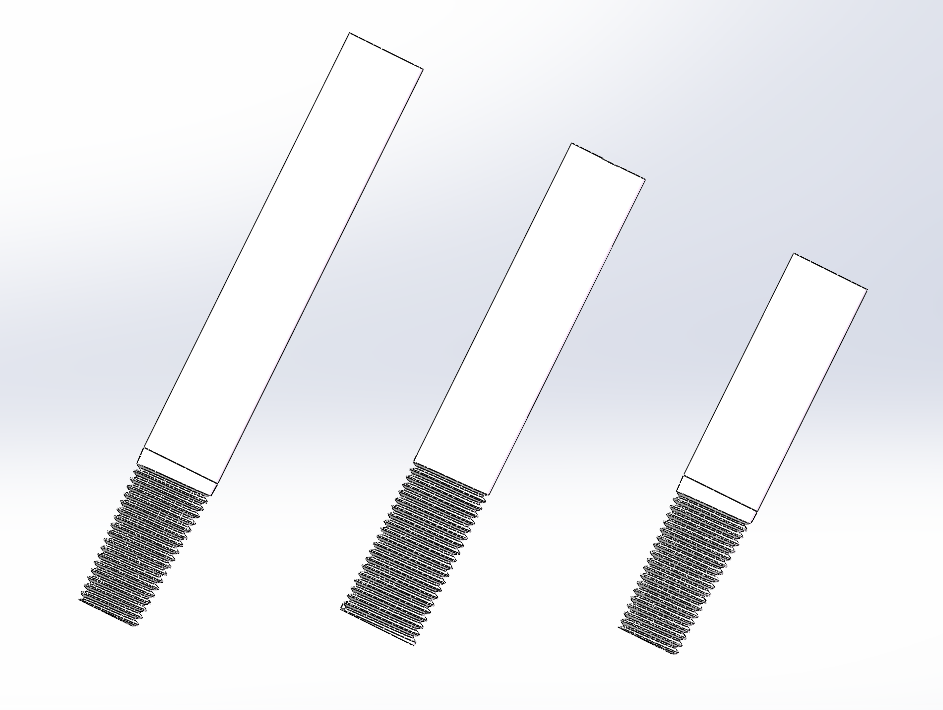

According to different thread standards, commonly used pipe threads can be divided into the following categories:

BSP stands for British Standard Pipe Thread and is commonly used in Europe and other countries that use the imperial system. BSP pipe threads can be divided into two types: BSPP and BSPT.

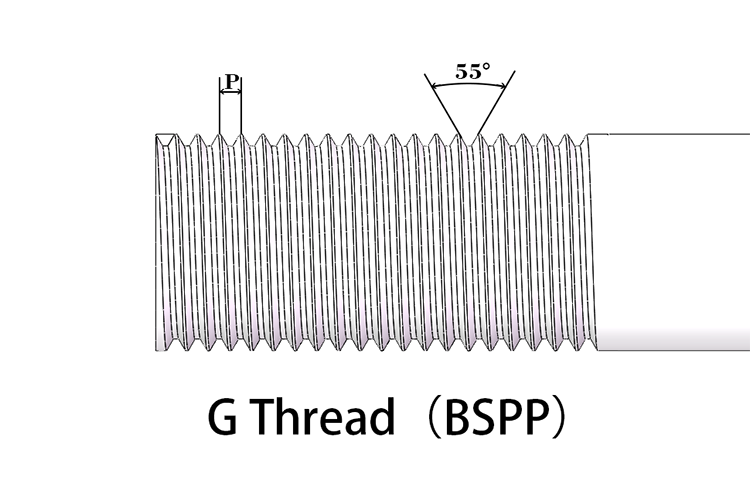

BSPP Threads:

BSPP stands for British Standard Pipe Parallel, commonly referred to as G threads. It has a thread angle of 55° and uses inches as its unit of measurement. It is a cylindrical thread, typically used for pipe connections that do not require sealing, or sealing is achieved externally.

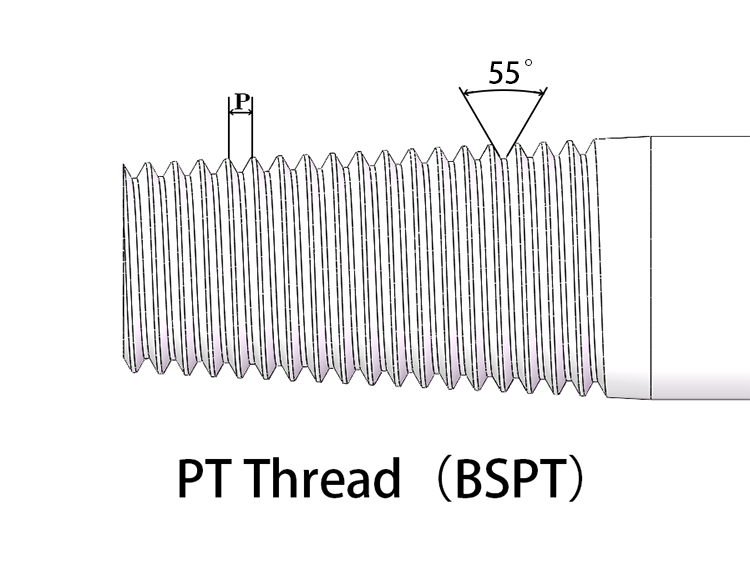

BSPT Threads:

BSPT stands for British Standard Pipe Tapered Thread, commonly referred to as PT threads. It also has a thread angle of 55° and uses inches as its unit of measurement. It is a tapered thread with a 1/16 taper. This allows it to create a seal through the compression of the threads, making it suitable for high-performance sealing applications like liquid transport, oil, and gas.

However, it is important to note that due to manufacturing tolerances and shape errors, its seal is not entirely reliable in practice. Therefore, additional sealing materials are often used to enhance its sealing capability.

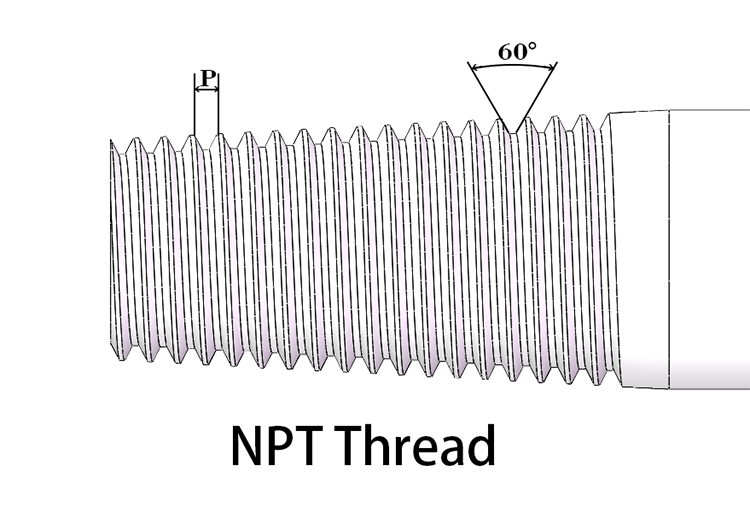

American Standard Pipe threads are widely used in North America for various pipe connections and international trade. Compared to the British PT threads, American pipe threads have a thread angle of 60° and a flat-top, flat-bottom profile. The same pipe series has a larger pitch, and the major diameter is also larger, with stricter tolerance requirements. This makes them suitable for applications requiring high-temperature and high-pressure sealing.

NPT threads:

NPT is the abbreviation for National Pipe Thread, a standard pipe thread used in the United States. It is the most commonly used American pipe thread, with a history dating back to the late 19th and early 20th centuries, evolving from the thread standards established by Robert Briggs.

NPT threads are commonly used for connecting pipes and fittings, especially in water, gas, and liquid pipe systems, and are widely used in international trade in North America.

Unlike British threads, NPT pipe threads have a 60° thread angle. They are also tapered threads with a 1/16 taper, providing self-sealing properties.

It is measured in inches, and the size code represents the nominal diameter of the pipe where the thread is located, such as 1/8''NPT, 1/4''NPT, 1/2'' NPT, etc.

NPTF threads:

NPTF threads were introduced in the early 20th century. In the original NPT standard, the tolerance range was quite large, which could lead to leakage at the connection points.

Therefore, NPTF threads were introduced to ensure better sealing performance and higher leak prevention by implementing stricter tolerances and design. The precision of the individual thread parameters is higher than that of NPT threads, and the fit between the thread crest and root is an interference fit.

As a result, NPTF threads are generally more expensive and are used in applications where strict sealing requirements are essential.

The earliest metric sealing pipe thread was the DIN 1580 standard established in Germany in 1954. However, due to certain historical reasons and the specific nature of piping products, this thread has not been widely accepted by most countries around the world to this day.

Different pipe thread connections can use different sealing methods.

PTFE Sealant Tape:

PTFE (Polytetrafluoroethylene) sealant tape is soft and easy to use, providing excellent sealing performance and not reacting with fluids. It is suitable for pipe systems carrying water, air, oil and gas, steam, and other media.

Pipe Sealant Glue:

Pipe sealant glue is typically made from organic solvents and materials such as rubber and resin. It forms a strong sealing layer at the thread joint, preventing leakage of the medium, and is suitable for high-pressure and high-temperature environments. It is more suitable than sealant tape for high-strength and high-pressure applications.

Sealing Rings and Gaskets:

Some joints come with built-in sealing rings or gaskets, which make it easy to seal the joint. They are also suitable for situations requiring additional sealing, such as in chemical medium pipelines or steam pipelines.

Fokca is a professional manufacturer specializing in various pneumatic components. We offer a variety of different sizes of fittings, tubes, and cylinder accessories, with multiple thread types available for selection. If you have any needs, please click here to visit our Product page for more information.

You can also click here to visit our Blog page, where we provide a series of more detailed and comprehensive articles, images, and videos to help you better understand pipe threads and pneumatic tube fittings.

You May Interest In

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap