Jan 17, 2023

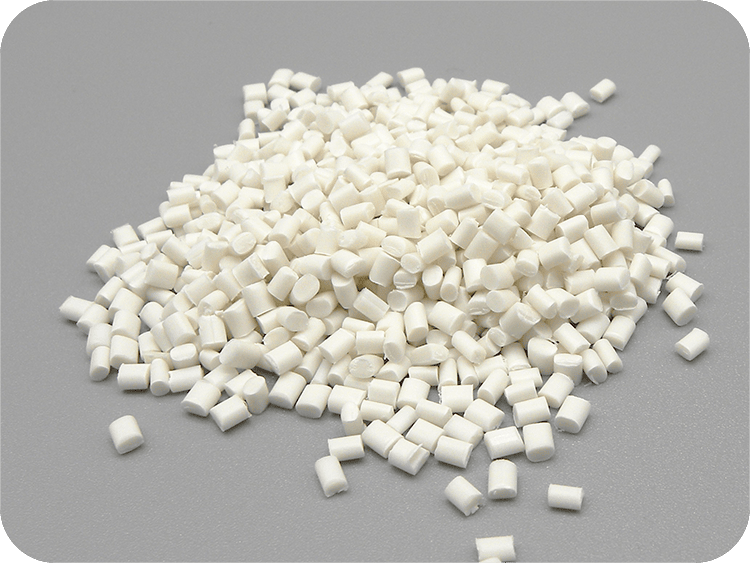

Plastic, a seemingly ordinary yet ubiquitous material, is widely used in modern industry and daily life due to its versatile forms, excellent performance, and strong versatility. You must have heard of familiar plastic materials such as polyvinyl chloride and nylon.

However, have you ever thought about the similarities and differences between those various plastic materials? And what are the classification of plastics?

Polyamide (nylon) | |

Polyoxymethylene | |

Polyurethane | |

Polyethylene | |

Polypropylene | |

Polyvinyl Chloride | |

Polytetrafluoroethylene | |

Perfluoroalkoxy polymer | |

Fluorinated ethylene propylene copolymer | |

Polyethylene terephthalate | |

Acrylonitrile butadiene styrene copolymers |

PA stands for Polyamide, commonly abbreviated as nylon, and has a wide range of applications in various industries such as clothing, home textiles, industrial products, medical supplies, electronic products, and automobiles.>

Nylon material has good wear resistance, impact resistance, mechanical strength, and heat resistance, as well as high chemical stability, which can resist the erosion of chemical substances such as acid, alkali, and oil. Meanwhile, nylon is also resistant to organic solvents,which makes it widely used in chemical, petroleum, and other fields.

However, its light resistance and low temperature resistance are poor, and it is not resistant to strong acids and alkalis, which requires high requirements for injection molding technology. This to some extent limits the application of nylon.

Nylon materials have various branching categories, such as PA6, PA11, PA12, etc., and their respective characteristics also have some differences:

| Characteristics | PA6 | PA11 | PA12 |

Strength and toughness | High strength and toughness | High impact strength and toughness | Balance of strength, toughness, and impact resistance |

Chemical resistance | Good chemical resistance and durability | Corrosion resistance | Chemical corrosion resistance and oil resistance |

Heat resistance | Melting point approximately 215 ℃ | Melting point is about 185 ℃ | Melting point between 175 ° C and 185 ° C |

Water absorption | Relatively high | Lower (0.1-0.4%) | Lower moisture absorption |

Processing capability | Wide temperature range and good processability | Diversity in Processing and Forming | Good liquidity, easy to process |

Other characteristics | Good wear resistance and self-lubricating properties | Cold resistance and fatigue cracking resistance | High transparency and excellent dimensional stability |

POM, also known as Polyoxymethylene, has excellent comprehensive properties and is one of the hardest varieties of thermoplastic materials. Its mechanical properties are close to those of metals, and its tensile strength, bending strength, fatigue strength, wear resistance, and electrical properties are all excellent.

It is widely used in the manufacturing of components such as gears, bearings, pipelines, valves, etc. that require high strength and wear resistance, as well as in the packaging of aerosols, oil pipelines, etc.

PU, also known as Polyurethane, has excellent physical and chemical properties such as high elasticity, toughness, wear resistance, aging resistance, oil resistance, and chemical corrosion resistance.

It uses synthetic fibers as raw materials and can be processed into various shapes and sizes through various processes, with excellent properties such as easy processing, environmental friendliness, and waterproofing. Its price is moderate, and its appearance can be improved through processes such as dyeing and printing.

These characteristics have enabled PU materials to have a wide range of applications, such as industrial production, medical equipment, food processing, home furnishings, and electronic products.

The full name of PE is Polyethylene, which has good mechanical strength and chemical stability, and can resist most acid-base erosion. Its density is low, making it easy to transport and process, while also having electrical insulation properties. Widely used in various types of films, pipelines, containers, wires and cables, and daily necessities.

According to different densities, it can be divided into HDPE, LDPE, and LLDPE , each with different application scenarios.

Characteristics | HDPE | LDPE | LLDPE |

Full name | High Density Polyethylene | Low Density Polyethylene | Linear Low Density Polyethylene |

Softening point (℃) | 125-135 | 90-100 | 94-108 |

Mechanical property | High strength, toughness, and rigidity | Poor mechanical strength | High strength, toughness, and strong rigidity |

Heat resistance | Preferably | Poor | Preferably |

Cold resistance | Preferably | Preferably | Preferably |

Chemical resistance | Resistant to strong oxidants, acid-base salts, and organic solvents | Acid, alkali, and salt aqueous solutions | Acid, alkali, and organic solvents resistant |

Processing capability | Suitable for various processing methods | Easy to process | Good , but attention should be paid to shear sensitivity |

Main Purpose | Pipes, sheets, injection molded products, wires and cables, etc | Film products (packaging film, agricultural film, etc.) | Thin films, pipes, injection molded products, etc |

PP, also known as Polypropylene, is a high-performance and widely used thermoplastic resin. Usually a colorless, transparent, or semi transparent solid. It has a low density and is one of the lightest varieties among all plastics.

At the same time, it has high strength and rigidity, good heat resistance, low temperature resistance, chemical resistance, and excellent processing performance.

It is widely used in fields such as building pipes, medical supplies, and food packaging due to its advantages.

PVC, also known as Polyvinyl chloride, is a widely used thermoplastic made by polymerizing vinyl chloride monomer. It has excellent corrosion resistance, insulation, flame retardancy, good stability to light and heat, and can be used outdoors for a long time without aging easily.

PVC can adjust its hardness and strength by adding different additives (such as plasticizers, stabilizers, etc.) to meet the needs of different applications.

It has a wide range of applications in multiple fields, including building materials, wires and cables, packaging materials, medical devices, and daily necessities.

PTFE, also known as Polytetrafluoroethylene, has the lowest friction coefficient and surface tension among solid materials, thus possessing excellent lubrication performance and non adhesiveness; Capable of withstanding strong acids and bases and almost insoluble in all solvents; It can maintain stability in both high and low temperature environments, and can be used for a long time in the range of -180 to 260 ℃.

Therefore, PTFE is widely used in the production of electrical components, food packaging, pipeline valves, medical implants, aerospace, and more. However, due to its non melting nature and direct decomposition under high temperature conditions, resulting in higher production costs compared to other plastics. At the same time, its pressure resistance is relatively poor, generally only capable of carrying low-pressure fluids and not suitable for high-pressure environments.

PFA, also known as Perfluoroalkoxy polymer, has properties similar to PTFE but with better transparency, processability, creep resistance, and compressive strength. It is mainly used in applications that require high temperature and chemical stability, such as semiconductor manufacturing, chemical processing, pharmaceuticals, and other fields.

FEP, also known as Fluorinated Ethylene Propylene Polymer, has good heat resistance and corrosion resistance, but is generally slightly lower than PTFE and PFA.

At the same time, it has good processability and transparency, with mechanical properties between PFA and PTFE, and good tensile resistance and flexibility.

Widely used in the production of beverage bottles, food packaging, synthetic fibers, etc. In addition, PET is also used to make films, sheets, and engineering plastics.

PET, also known as Polyethylene terephthalate, is a thermoplastic polyester material that is easy to process. It is typically light yellow or milky white in color, with a smooth and glossy surface, making it suitable for occasions that require high aesthetic standards.

PET has high strength, high rigidity, and good wear resistance. It has good resistance to most solvents and oils, and has low permeability to gases and water vapor, making it an ideal choice for packaging materials such as food and medicine .

However, its heat resistance is not high. The thermal deformation temperature of pure PET material is about 85 ℃, and its UV and corona resistance are also poor. When used in these situations, it needs to be treated with UV resistance or fiberglass reinforcement.

ABS, also known as Acrylonitrile Butadiene Styrene, is an easy to process thermoplastic that combines the chemical corrosion resistance of acrylonitrile, the elasticity of butadiene, and the rigidity of styrene. It has excellent overall performance and can be used in medium load and high-speed environments, especially exhibiting good toughness at low temperatures (-40 ℃).

At the same time, it is easy to print, coat, and color on the surface, has high glossiness, and meets environmental requirements.

Therefore, it is widely used in various fields such as automobiles, electrical appliances, building materials, packaging, furniture, etc.

However, its flame retardancy is poor and it is sensitive to ultraviolet radiation, which may not be ideal for scenarios that require high flame retardancy or long-term outdoor work.

The above are the types and characteristics of common plastics. The application of plastics covers all walks of life. In the field of pipe connection, plastic pipes of different materials have different characteristics.

FOKCA is a professional manufacturer ofpneumatic components, producing a wide range of high-quality fittings and pipes including PU pipes, nylon pipes, PE pipes, rubber and plastic hoses to meet your different needs and applications. You can click here to access our Product page for more information.

You can also click here to access our Blog page. We offer a range of more detailed and comprehensive articles, pictures and videos to help you better understand plastic pipes and tube fittings.

You May Interest In

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap