Dec 04, 2024

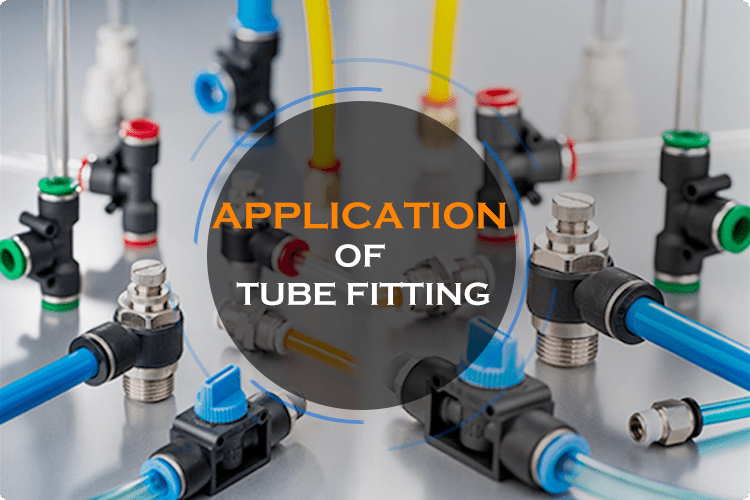

Pneumatic Systems: Tube fittings are essential for connecting cylinders, valves, and actuators, ensuring the stable and efficient operation of pneumatic systems.

With high-quality tube fittings, you can maximize performance and reliability in industrial automation.

Hydraulic Systems: Tube fittings are designed to securely transmit fluids under high pressure, making them vital in hydraulic systems across various industrial machinery.

Automation Machinery: Flexible and durable tubes and fittings are crucial in connecting robotic and automated systems, supporting smooth and efficient operations.

Fuel and Brake Lines: In aerospace and automotive applications, tube fittings ensure safe and reliable connections for critical fluid systems like fuel and brake lines.

These fittings are designed to handle extreme conditions and pressures.

Cooling Systems: Tube fittings play a key role in automotive and aerospace cooling systems, helping to efficiently transfer coolant and maintain optimal engine temperatures.

Laboratory Equipment: Tube fittings are commonly used in laboratory equipment for precise fluid and gas transfer, meeting the high-accuracy demands of medical and pharmaceutical industries.

Medical Devices: Tube fittings ensure the secure and reliable transfer of fluids and gases in medical devices like dialysis machines, ventilators, and life-support equipment, crucial for patient care.

Processing Equipment: Tube fittings provide hygienic and leak-free connections for fluid transfer in food and beverage production, adhering to stringent sanitation and safety standards.

Bottling Plants: In bottling plants, tube fittings are integral in ensuring a smooth, contamination-free transfer of beverages, guaranteeing product safety and efficiency in the filling process.

Heating, Ventilation, and Air Conditioning (HVAC): Tube fittings are widely used in HVAC systems to connect air conditioning, refrigeration, and heating components, ensuring efficient fluid and gas transfer across building systems.

Plumbing Systems: Tube fittings are critical for water distribution systems, enabling smooth and reliable fluid flow in residential and commercial plumbing applications.

Drilling Equipment: Tube fittings are designed to withstand extreme pressures, making them essential for safe fluid and gas transfer in oil and gas drilling operations.

Refineries: Tube fittings are used in refineries for secure, corrosion-resistant connections that safely transfer chemicals and gases in volatile environments.

Process Pipelines: Tube fittings are key to handling aggressive chemicals and volatile gases in process pipelines.

Their durable design ensures leak-proof performance, even under high-pressure and high-temperature conditions.

Laboratory Equipment: Tube fittings are essential in chemical laboratories, enabling accurate and safe transfer of chemicals and gases for experiments and analyses.

Power Plants: Tube fittings are used in power plants to connect steam and gas turbines, playing a critical role in efficient power generation by safely transferring fluids and gases.

Solar and Wind Energy Systems: Tube fittings are also used in renewable energy systems, such as solar and wind power plants, to ensure smooth fluid transfer for cooling and lubrication systems.

Brass is a durable and corrosion-resistant material that offers good machinability. It is commonly used for general-purpose connections where a balance of strength and cost-effectiveness is required.

Excellent corrosion resistance, particularly in water and air.

Easy to machine and fabricate.

Non-sparking, making it safe for certain environments.

Copper is highly conductive and provides superior corrosion resistance. Purple copper (or deoxidized copper) is particularly resistant to oxidation, making it suitable for environments where high durability is required.

Excellent resistance to corrosion and oxidation.

High thermal conductivity, ideal for heat transfer systems.

Malleable and easy to weld or form into different shapes.

Stainless steel tube fittings is known for its high strength, durability, and resistance to corrosion, even in harsh environments. It is often used for applications that require high pressure and temperature tolerance.

Exceptional corrosion resistance, especially in acidic or alkaline conditions.

High tensile strength and resistance to wear.

Long-lasting and durable, making it suitable for demanding conditions.

Plastic tube fittings are lightweight, cost-effective, and offer good resistance to corrosion, particularly in chemical environments. They are easier to install and handle compared to metal fittings.

Lightweight and easy to install, reducing labor costs.

Corrosion-resistant, especially in acidic or alkaline environments.

Cost-effective and versatile for various systems where high strength isn’t critical.

You May Interest In

Feb 24, 2025 Blog

How to Identify Hydraulic Quick Couplers?

Jan 21, 2025 Blog

How to Measure Pipe Thread?

Jan 16, 2025 Blog

What Is Pipe thread?

Dec 04, 2024 Blog

Application Of Tube Fitting

Jun 26, 2023 Blog

What Is The Difference Between LLDPE And LDPE?

Jan 17, 2023 Blog

What Are The Classification Of Plastics?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap