Mar 25, 2025

Silicone tubing is widely used across various industries, including medical, food processing, and industrial applications, due to its flexibility, durability, and resistance to extreme temperatures. This guide covers essential information about silicone tubing, including how to cut, clean, and stretch it, as well as its safety and resistance properties.

Cutting silicone tubing requires precision to ensure clean and even edges. Here are the recommended steps:

◆ Measure and Mark – Use a ruler and a marker to mark the desired length.

◆ Use a Sharp Blade – A razor blade, scalpel, or sharp scissors can provide a clean cut.

◆ Secure the Tubing – Hold the tubing firmly or use a cutting board to prevent movement.

◆ Cut Straight – Apply steady pressure to avoid uneven edges that could affect its functionality.

Cleaning silicone tubing properly helps maintain hygiene and extend its lifespan. Follow these steps:

◆ Rinse with Warm Water – Flush the tubing with warm water to remove debris.

◆ Use Mild Detergent – A gentle soap or a food-safe cleaning solution is recommended.

◆ Sanitize If Needed – For medical or food applications, sterilization methods such as boiling, autoclaving, or using a disinfectant solution can be used.

◆ Dry Thoroughly – Allow the tubing to air dry completely before use to prevent bacterial growth.

Silicone tubing is flexible but may need stretching for specific applications. Here’s how to do it safely:

◆ Warm the Tubing – Heating the tubing slightly with warm water or a heat gun can increase flexibility.

◆ Use a Lubricant – A food-safe lubricant or soapy water can help reduce friction.

◆ Apply Gradual Force – Stretch the tubing gently over the desired fitting or object to avoid tearing.

Yes, silicone tubing is commonly used in food and beverage applications because it is non-toxic, BPA-free, and resistant to high temperatures. Food-grade silicone tubing meets FDA and other regulatory standards, ensuring safety for contact with liquids and consumables.

Silicone tubing has excellent chemical resistance, but it is not recommended for fuel or petroleum-based liquids. Exposure to fuels like gasoline or diesel can cause the tubing to degrade. For fuel applications, alternative materials such as Viton or PTFE tubing should be considered.

Silicone tubing is available from various suppliers, including industrial distributors, online marketplaces, and specialized manufacturers. When purchasing, consider factors such as size, wall thickness, temperature resistance, and intended application to ensure compatibility.

Fokca provides high-quality silicone tubing suitable for various industries, including medical, food processing, and industrial applications. Our silicone tubing is durable, flexible, and resistant to extreme temperatures, ensuring reliable performance in demanding environments. Contact us to learn more about our silicone tubing options and customization services.

If you want to know more about this Silicone tubing, Please Contact us!

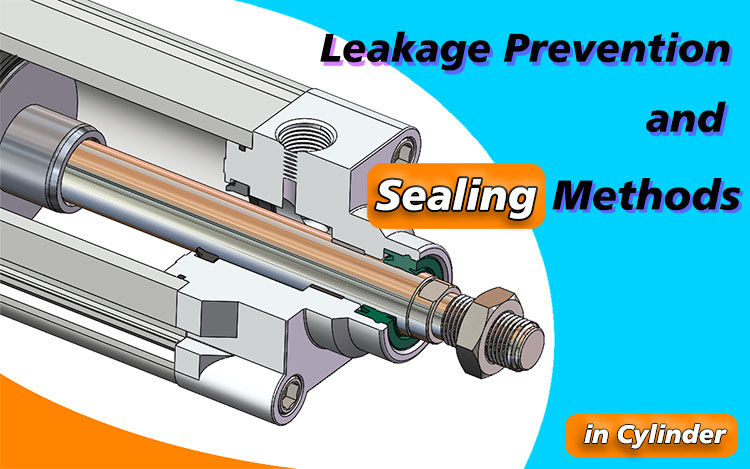

Leakage Prevention and Sealing Methods in Cylinder

Leakage Prevention and Sealing Methods in Cylinder

A Comprehensive Guide to Silicone Tubing: Cutting, Cleaning, Stretching, and More

A Comprehensive Guide to Silicone Tubing: Cutting, Cleaning, Stretching, and More

How to Choose the Right UV Resistant Polyurethane Tubing

How to Choose the Right UV Resistant Polyurethane Tubing

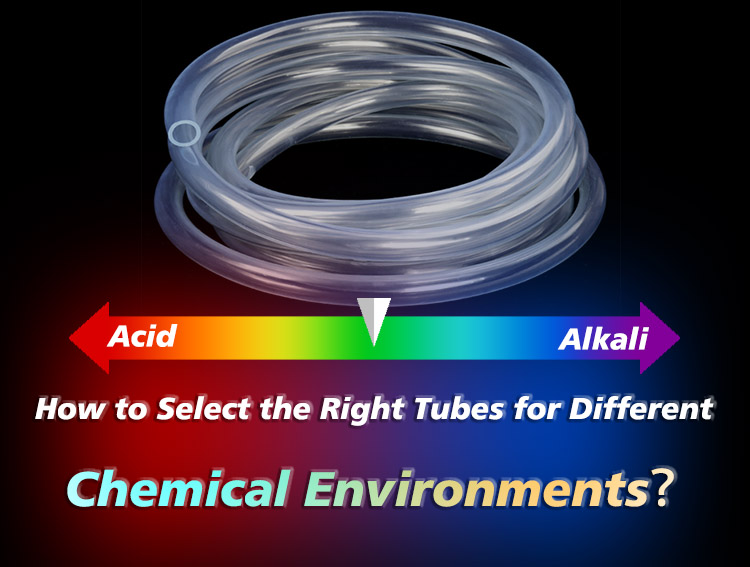

How to Select the Right Tubes for Different Chemical Environments?

How to Select the Right Tubes for Different Chemical Environments?

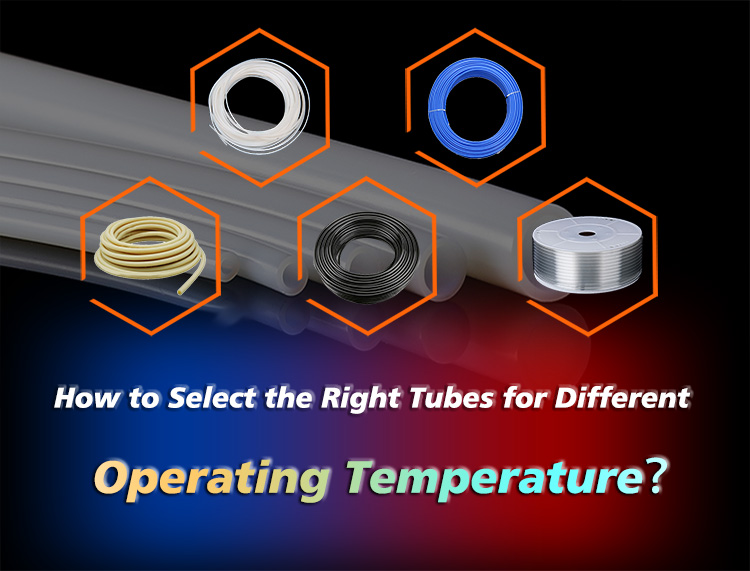

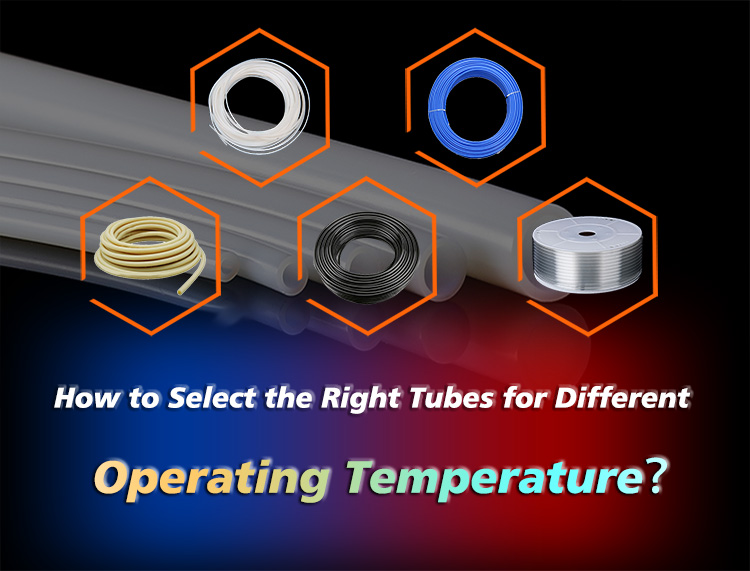

How to Select the Right Tubes for Different Operting Tempurature?

How to Select the Right Tubes for Different Operting Tempurature?

You May Interest In

Mar 13, 2025 Blog

What is Nylon Tubing?

Mar 10, 2025 Blog

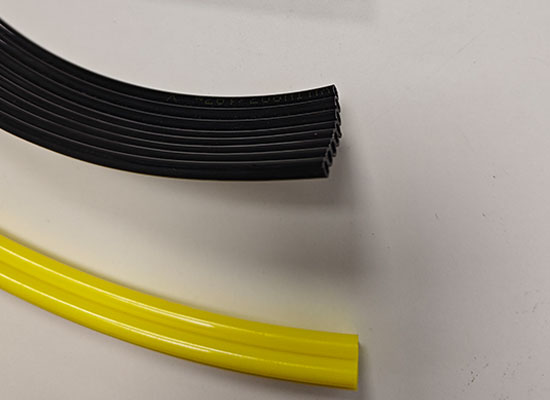

Multi-Row Pu Hose Customization

Mar 10, 2025 Blog

Metallic tube Customization

Mar 06, 2025 Blog

Nylon 11 and Nylon 12 Tubing Customization

Feb 10, 2025 Blog

Food Grade Polyurethane: What You Need to KnowLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap